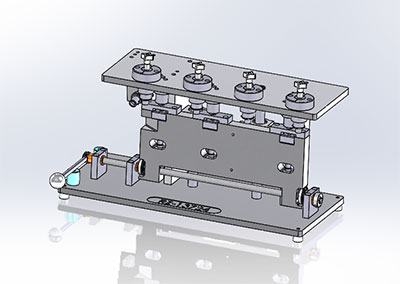

Project: Designed Gauges for GM

The Problem

Our connection in the General Motors (GM) engineering departments reached out to the ADS team to design custom gauges that were needed in the quality inspection process to ensure the GM part would meet customer specifications and industry quality standards.

The ADS Solution

The ADS design and engineering team worked with our contact to create a custom gauge to check and verify product length specifications after they exited the production line. The ADS team designed a gauge component to locate and measure the part to ensure it meets quality standards.

The Result

The ADS team designed quality audit gauges that are able to measure and verify exact part specifications. These gauges help streamline the GM quality manufacturing process by Verifying the automation processes and machines are producing quality products. When quality audits are performed and the product is out of spec, it alerts the manufacturing process team that an issue with their machine needs to be addressed.