Project: Robot for Maris Systems

The Problem

Maris Systems came to us because their engineering team staff was overloaded and needed assistance in creating a robot cell to integrate into their customer’s existing manufacturing process. Their customer had a tight timeline with a limited design cost budget, so the ADS design and engineering team worked with them to develop a robot design that would work within their specifications.

The ADS Solution

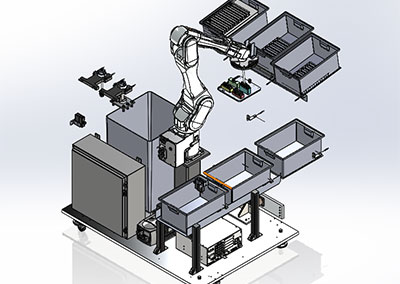

The ADS design and engineering team created a custom robot and developed a design to retrofit the new equipment into the customer’s existing manufacturing equipment system. A custom docking station was constructed for the robot to easily move the entire unit and attach it to the manufacturing line.

The robot was designed with three different configurations based on assembly requirements and included custom tooling design work for precision movement to meet quality requirements.

The Result

With the new robot, ADS helped Maris Systems reduce manufacturing costs and increase efficiency in their assembly process. Although this design and build was a high labor project, the ADS team worked with Maris Systems to produce the robot within their budget and timeline restrictions.